What is What?

Scroll down to find our drawings

From wikepedia:

A near miss is an unplanned event that did not result in injury, illness, or damage – but had the potential to do so. Only a fortunate break in the chain of events prevented an injury, fatality or damage; in other words, a miss that was nonetheless very near. Although the label of 'human error' is commonly applied to an initiating event, a faulty process or system invariably permits or compounds the harm, and should be the focus of improvement. Other familiar terms for these events is a "close call", or in the case of moving objects, "near collision" or a near hit.

You will discover that the database contains a wide range of different unsafe conditions mixed with a lot of unintented events, which almost resultated in an accident.

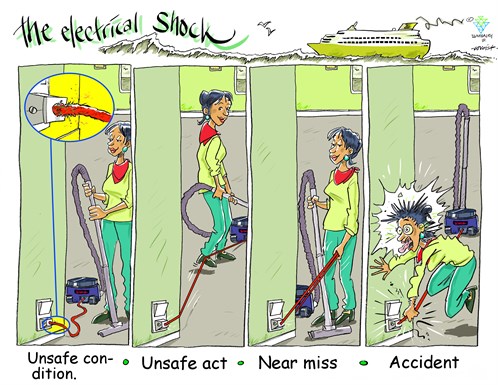

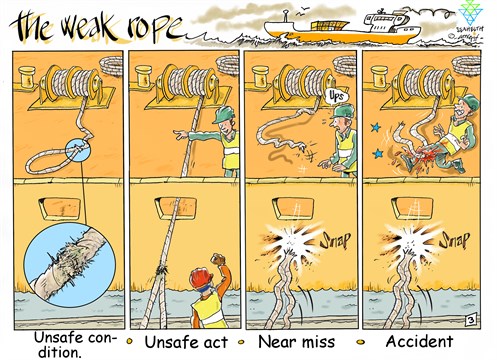

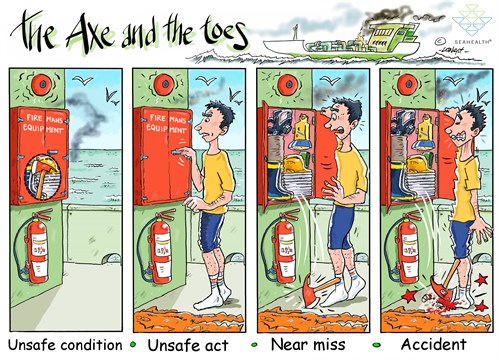

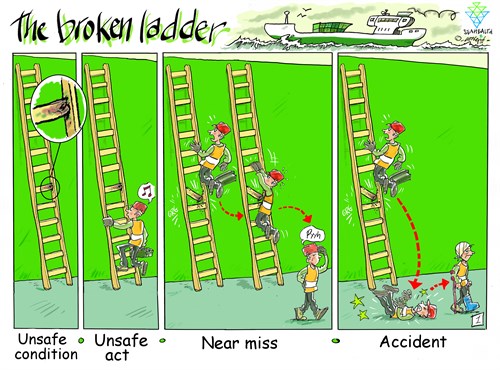

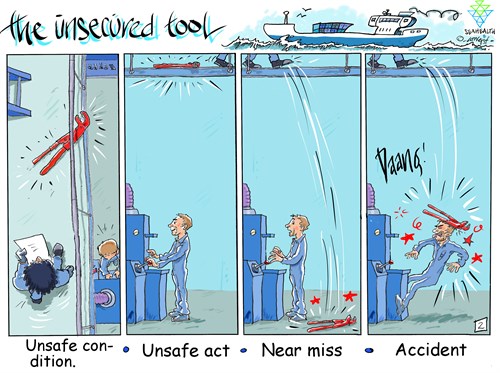

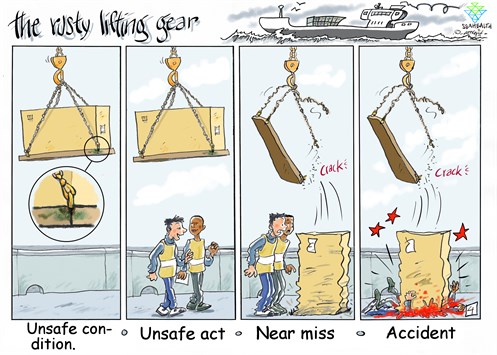

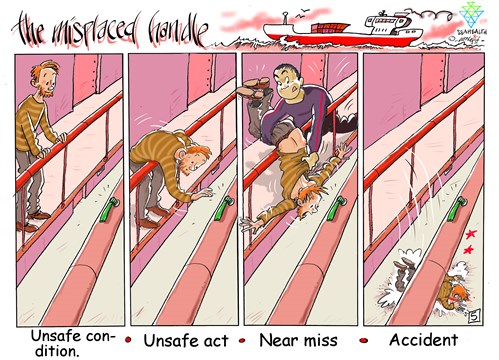

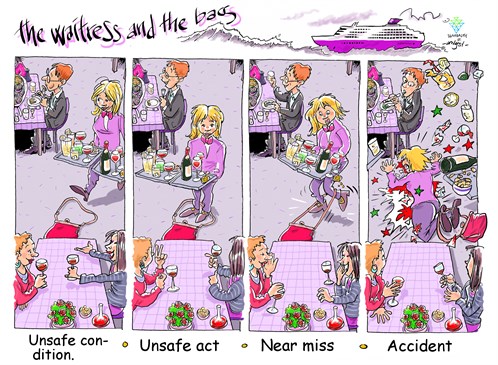

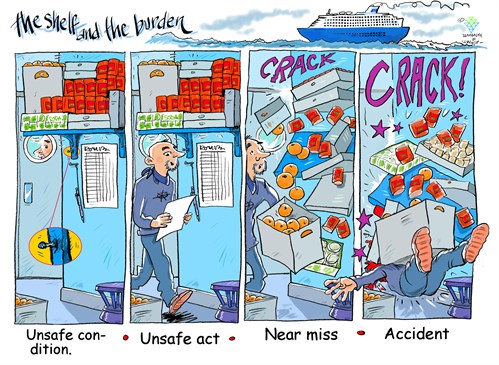

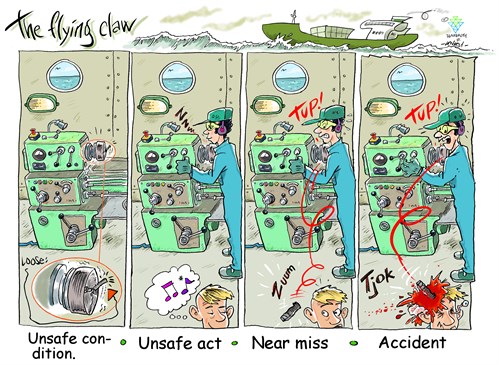

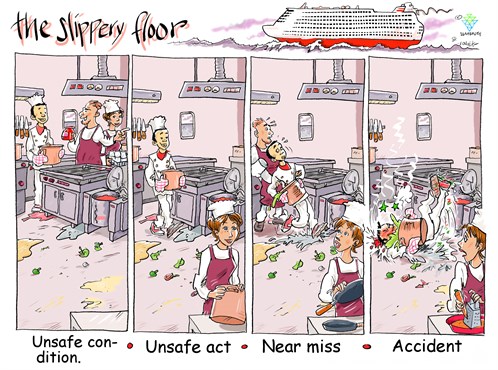

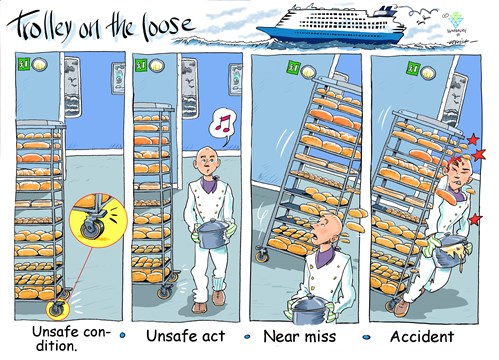

As many of the shipping companies already has developed their own definition of a near miss, SEAHEALTH has chosen not to have a official definition of a near miss at this stage, but would like to invite the industry to differ between the 4 terms:

- Unsafe condition

- Unsafe act

- Near miss

- Accident

In order to explain the differences between the terms we have created several cartoons. (Scroll down the page to see them all)

If we are able to spot the unsafe conditions there is a high likelyhood that we can avoid the unsafe act, near miss and accident.

If we are able to alert each other and have a high safety awareness we would be able to stop the unsafe act, avoiding the near miss and accident.

If we miss the two first opportunities we still have one more chance to avoid the accident. Namely: report and discuss the near miss, in order to prevent the personal injury or accident to hull and machinery.

SEAHEALTH is fully aware that the way accidents are build up can be much more complex than perceiving the series of events like this - but as a start we believe most of the reasons can be found by spotting the hazardous working processes from the left.

Use the cartoons with your workmates to discuss if you agree upon our terms and how you can prevent the nearmiss by spotting the unsafe act and - condition.

The drawings should only be conceived as a way to illustrate the different terms. You could find many other errors when it comes to good safety behaviour.

Invisble or "hard to see" conditions

In your talk, please also consider also the unsafe conditions, which are hard to see or invisible in your daily work. Things like:

- a poorly written procedure that doesn't comply with the way things are done operationally

- a bad risk assessments that the ratings don't take ownership upon

- fatigue whicht affects the way people react or think

- recklessness which undermines the overall safety

- complacency. You have done it many times before without any accidents, so why should it be dangerous?

- unspoken accept. If the leaders on board don't interfere with unsafe acts, the behaviour would be perceived as "the way people do things around here"

- busyness which in many cases contributes to short cuts and people not stopping and thinking before doing the job

- bad radio discipline which can contribute to people getting too much information or not sufficient information

- lack of training/education, which can contribute to people not being skilled for the job and therefore putting themselves and others in danger.

Get the drawing The Weak Rope

Get the drawing The Axe And The Toes

Get the drawing The Broken Ladder

Get the drawing The Unsecured Tool

Get the drawing The Rusty Lifting Gear

Get the drawing The Misplaced Handle

Get the drawing The Waitress And The Bag

Get the drawing The Shelf And The Burden

Get the drawing The Flying Claw

Get the drawing The Slippery Floor

Get the drawing Trolley On The Loose

Get the drawing The Electrical Shock